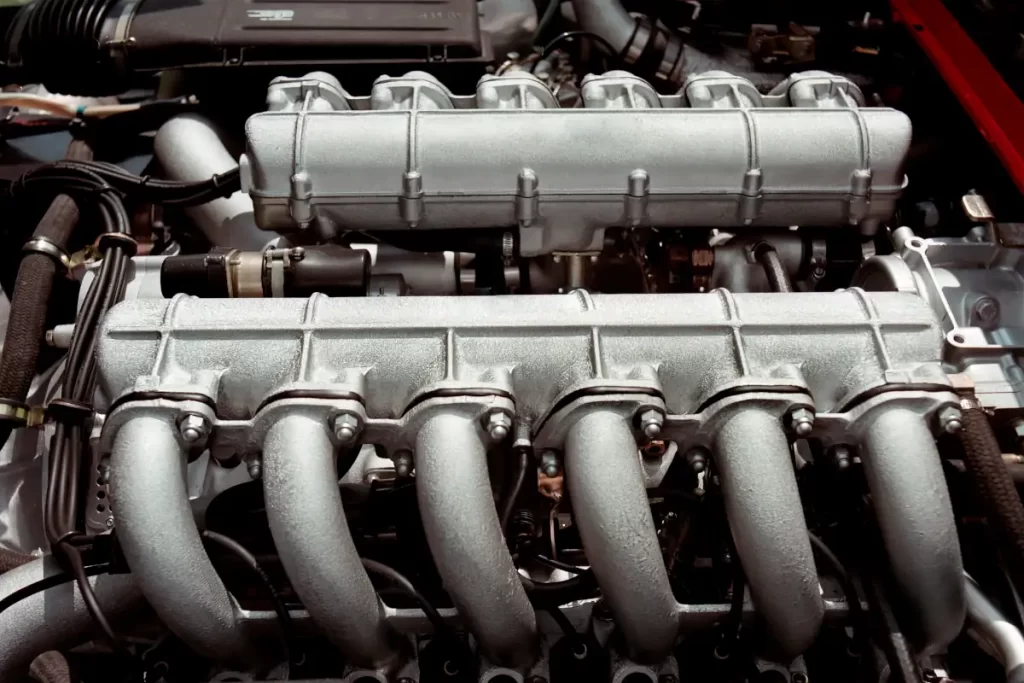

Your car exhaust manifold is a vast metal bolted to the engine’s side. It usually links the exhaust tailpipe to its main engine block. You will find it fixed with bolts near the engine.

Since it’s a solid structure unto which the exhaust tailpipe is bolted, you may wonder if the car exhaust manifold bolts need to be torqued to maintain the good performance of the exhaust manifold. Also, what will happen to the car exhaust manifold if you do not apply the correct torque?

We shall look at each question and give you a solved and explained answer. Let’s get started.

Let’s Find Out If Car Exhaust Manifold Bolts Need to Be Torqued

Yes, car exhaust manifold bolts need to be torqued. When installing a car exhaust manifold, you must carefully and appropriately torque the bolts by applying 20 to 30-foot pounds of torque. This is usually a standard amount; hence it can change with different car exhaust manifold bolts. You will use between 15 to 20 pounds of torque for a much older car exhaust manifold.

By you torquing your car exhaust manifold bolts, you end up getting the following:

Comfortable Driving Experience

If the toque is applied well, you will not have to downshift the gears frequently during accelerating from low speeds hence enjoying a comfortable ride. In addition, there will be no leaks since the manifold bolts will be well-tightened.

The chances of debris accumulating in car exhaust manifolds because of leaks will be minimal.

Smooth Transportation of Heavy Loads

Applying torque to car exhaust manifold bolts will be beneficial, especially if you have a truck carrying heavy stuff. It will make your car exhaust manifold firm, making transporting heavy material more manageable and incredible.

Easy Travelling in Steep Inclines

If you have more torque on the bolts, it usually generates extra power to get your car moving even in steep inclines. So, torque on exhaust manifold bolts will help you when driving off-road and under unfavorable conditions.

Related:

- What Are Car Exhaust Manifold Bolts Made Of? (Answered)

- Do Exhaust Manifold Studs/Bolts Need Loctite or Anti-seize? (Explained)

- Why Do Exhaust Manifold Bolts Break? (Solved)

How Much Torque Is Required for Car Exhaust Manifold Bolts?

Each car has the torque required to tighten its exhaust manifold bolts adequately. The standard amount is between 20 to 30-foot pounds of torque. It will be less for much older car exhaust manifolds, like 15 years old. You will use between 15 to 20-foot pounds of torque.

Other manifolds usually contain different plugs and sensors, like exhaust plugs and check valves. These various types usually need less torque than the manifold bolts. You will only use a range of 10 to 17foot pounds of torque for the elements.

If you want to know the specific amount of torque for your car manifold bolts, you can find it in your vehicle’s-specific repair manual at the auto parts retailer.

When torquing, you will have to remove any warn out or used gasket material and then fix a new gasket when you have disassembled the manifold from the car.

You will have to torque the bolts well by following a sequence. This will assist the replaced gasket with getting positioned appropriately against the engine, blocking leaks.

Ensure you torque the bolts in a pattern and use the first half of the required torque. Begin with the center bolts, then adjust towards the edge with one bolt at a time. Rewind the process until you have accomplished the required torque.

What Happens to the Car Exhaust Manifold If the Correct Torque Is Not Applied?

If you don’t apply the correct torque, the joint will not operate as it is supposed and may break or get damaged entirely. With such rotating equipment, any breakage will lead to debris accumulation, which may interfere with your safety.

Correct bolt torque is not just for efficiency but also for safety.

Insufficient torque would manifest problems when the required load does not withstand the clamping force, making your passengers slide against each other or separate. It, in turn, makes the bolts bend and shear because of the load they cannot withstand.

Additionally, little torque usually reduces the bolts’ preload, lowering the threads’ friction and making the fasteners loosen after a short period.

On the other hand, excessive torque is also inappropriate because the bolts and passengers will not be considered preload. This will lead to clamping force being created, causing the removal of the threads and malfunctioning of the components.

To avoid such problems, use a torque wrench to ensure your bolts are correctly bolted. Even if you use the proper torque spec, you must check the bolts to see if they need to be longer, minor, or low-grade. You want the bolt power to meet the recommended preload for your joint.

So always check the grade and size of bolts needed for a smooth application.

You will find Hex head bolts with markings on the head specifically to denote the ANSI or ISO grade. For the remaining styles of bolts, please inquire with the supplier about their tensile power and any other torque rating information.

What If I Don’t Have a Torque Wrench to Tighten Car Exhaust Manifold Bolts?

A torque wrench is usually necessary since you want to tighten the bolts to specs and not go to the extent of overtightening them. However, some experienced mechanics usually tighten their bolts without using a torque wrench. Here is what you can use if you don’t have a torque wrench though you must watch out not to overtighten or under-tighten the manifold bolts.

Take a look.

Flex Head Ratchet

This tool has been available for quite some time. You can adjust it in different directions, like straight, to tighten the bolts well. Flex head ratchets usually access those grumpy nuts and bolts, so you can be sure that by using them, you will get a firm grip on your manifold bolts.

Universal Joint Adapters

You can find universal joint adapters in various sizes such as 1/4 inches, 3/8 inches, and 1/2 inches. They help you rotate a bolt or nut at 90 degrees.

If you don’t get the desired grip, you can take a ratchet and tighten the manifold bolts to get the proper grip.

Palm Drive Ratchet

The tool is also called a thumbwheel or finger. The good thing with them is that you do not have to apply more torque on them, but they will tighten your manifold bolts as required.

You can find a palm drive ratchet with a gimble handle for flexibility. Also, you can access it in entire sorts of drivers.

Knurled Extension

While using this extension, the large knurl on the body will help you tighten the bolts without necessarily using the other handle attached. You can get knurled extensions of different sizes and lengths.

Nut Drivers

Almost every car owner has a nut driver. You can add a socket driver handle for versatility while tightening the manifold bolts.

Ratcheting Box Wrenches

Ratcheting box wrenches usually perform best with manifold bolts in tight quarters. You can get them in different configurations like deep offset, flat, shallow offset, and so on. Also, they are in different sizes and lengths, giving you various choices.

Conclusion

Like any other bolts, your car exhaust manifold bolts must be torqued using a wrench. It will help give you a comfortable ride, prevent leaks, and offer smooth transportation of heavy loads.

Ensure you torque the bolts correctly; Don’t overtighten or under-tighten them. Use the correct tightening options provided in this article for a safe journey.

Sources

The Importance of Knowing and Following the Torque Specs

Should I Reuse my Exhaust Manifold?